Allen Face, Author of the Fmin System

Fmin is the most advanced method available for gauging a floor’s ability to support wire- or rail-guided lift truck traffic in narrow aisle warehouses. The system directly controls future vehicle motions by limiting all six of the surface variables that affect hard-axle vehicle motions.

For controlling profile quality, every concrete floor falls into one of two categories determined by the type of traffic the floor is intended to support. If the traffic is constrained by guide wires or guide rails to run along specific paths – as in the case of a narrow-aisle warehouse serviced by turret trucks – then the floor is in the Defined Traffic category. Any other type of traffic puts the floor in the Random Traffic category. Fmin applies to Defined Traffic Floors.

Very Narrow Aisle (VNA) Warehousing

Defined Traffic Floors are installed in very narrow-aisle (VNA) warehouses serviced by turret trucks. Operational efficiency in this type of warehousing is determined by the number of pallets handled per truck per hour – which ratio is determined in large part by the flatness/levelness of the tracks in which the lift truck wheels must roll.

Previous

Next

The Fmin number sets the maximum cross-aisle (transverse) and down-aisle (longitudinal) ride roughnesses and the mast tilt values to be tolerated

The turret truck manufacturers strive to achieve higher truck speeds, increase truck stability, and reach greater rack heights to increase productivity.

Without a flat and level floor on which to run, however, their efforts are worth nothing. If the floor is too bumpy, the truck will shake too much, and the driver won’t drive the truck at top speed. More trucks will be needed to move the same number of pallets, and the anticipated advantages of the warehouse will be diminished.

The proprietary F-min System – created and controlled by Allen Face – limits the side-to-side and front-to-back tilts, angular velocities, and angular accelerations to be experienced by a hard-axle vehicle of known wheel configuration travelling along its intended wheel tracks

Limiting Floor Tolerances for VNA Operations

As a consequence, floor requirements have to be well-specified and those variables that affect the truck’s movements must be limited. Unfortunately the gaps under 1, 2, 3, and 4 meter long straightedges are not the variables that influence truck movements. For this reason, the specification formats employed in DIN 15185 and VDMA are not effective.

The six surface variables uniquely limited by Fmin (no other system employs this dynamic simulation approach) control the movements of a truck as it moves across the floor (for more information on the six variables go to ‘Specifier’s Guide to F-Numbers’)

The Fmin System (developed by Allen Face in 1979) is used to control the wheel track profiles on all Defined Traffic floors. Fmin directly limits each wheel track’s influence on the truck’s angular displacements, angular velocities, and angular accelerations around both its pitch and roll axes. Fmin is thus a full-fledged Vehicle Simulation System that controls both the statics and dynamics of the truck at all locations within the aisle.

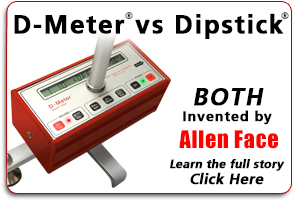

D-Meter makes measuring F-min simple

Fmin tolerances have traditionally been measured using a “differential floor profileograph” (invented by Allen Face and his father in 1976). In the spring of 2006 Allen Face developed a special new software package for the D-Meter allowing the instrument – operated by anyone – to generate the same levelness data produced by the profileograph – plus the essential flatness data that cannot be measured accurately by any profileograph. The D-Meter’s accuracy in gauging all 6 of the Fmin tolerance components was shown to be far superior to that of the profileograph, and much to the customer’s satisfaction, the associated testing and re-testing costs were also greatly reduced.